CB.D2 Receiving System

Receiving system to suit proportional or bang bang valves, with optional elevating mast control.

CB.DUO2 RECEIVING SYSTEM

Dual receiving system to suit proportional or bang bang valves, with optional elevating mast control.

Challenges for earth moving

High-precision levelling is very important for modern construction sites. An even, smooth surface is crucial for the quality of the overall project. For this reason, construction sites and their processes are getting more and more complex. The requirements on the worksite management are increasing and the tasks for machine operators are growing. In addition, construction projects, such as excavating a trench or complete earthworks and civil engineering projects must be implemented quickly and cost-effectively.

Productivity

The operator can only visually estimate the excavation depth. Additional control measurements are required after each step leading to increased re-work.

Machine Wear

Additional re-work results in more operating hours for your machine which in turn increases machine wear and requires earlier replacement.

Operating Costs

Inefficient, uncontrolled levelling requires more passes, increases working hours and fuel consumption.

Solutions

01

ECONOMICAL RECEIVING SYSTEM TO SUIT BANG BANG VALVES

CB.2001 Receiving System

- Suits bang bang valves

- 3 accuracy settings

- Economically priced

- Toggle switches

- Works with MOBA laser receiver R.ULS

CB.2001 System Components

02

VERSATILE RECEIVING SYSTEM WITH OPTIONAL MAST CONTROL

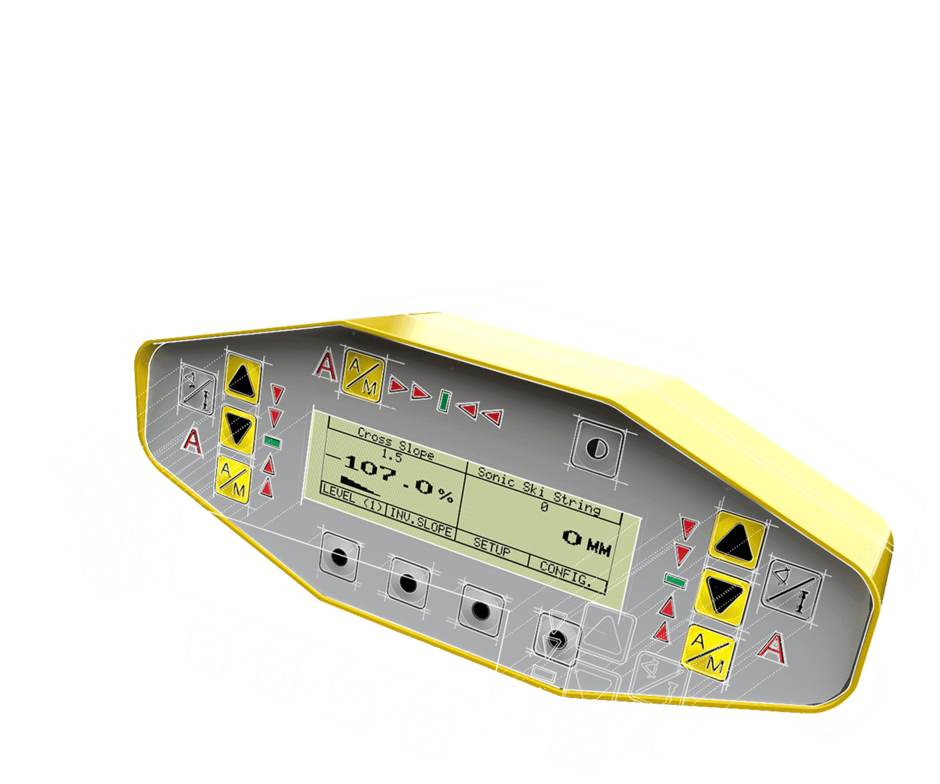

CB.D2 Receiving System

- Suits proportional or bang bang valves

- 3 adjustable accuracy settings

- Large, easy to read LCD display

- Machined die-cast aluminium housing

- Works with MOBA laser receivers and slope or ultrasonic sensors

- Optional elevating mast control

CB.D2 System Components

03

DUAL RECEIVING SYSTEM WITH OPTIONAL MAST CONTROL

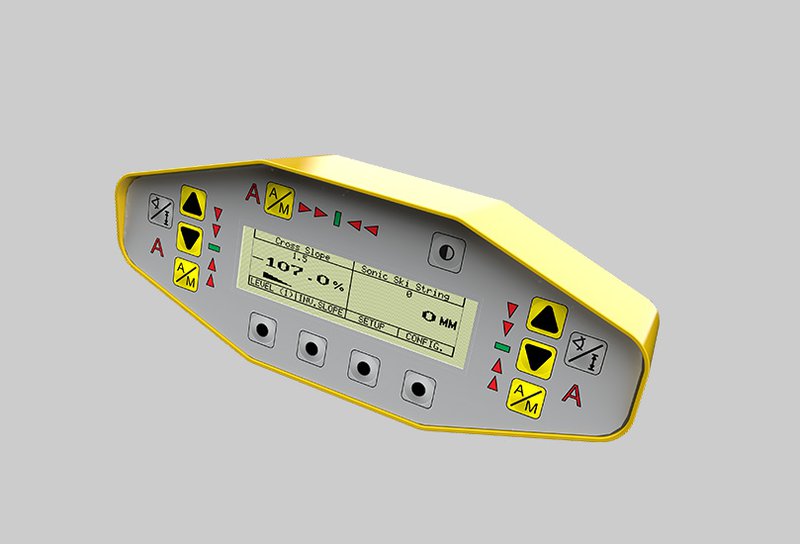

CB.DUO2 Receiving System

- Suits proportional or bang bang valves

- 3 adjustable accuracy settings

- Large, easy to read LCD display

- Machined die-cast aluminum housing

- Works with MOBA laser receivers and slope, ultrasonic and GNSS sensors

- Optional elevating mast control

CB.DUO2 System Components

04

Perfect fine-grained surface, best Results

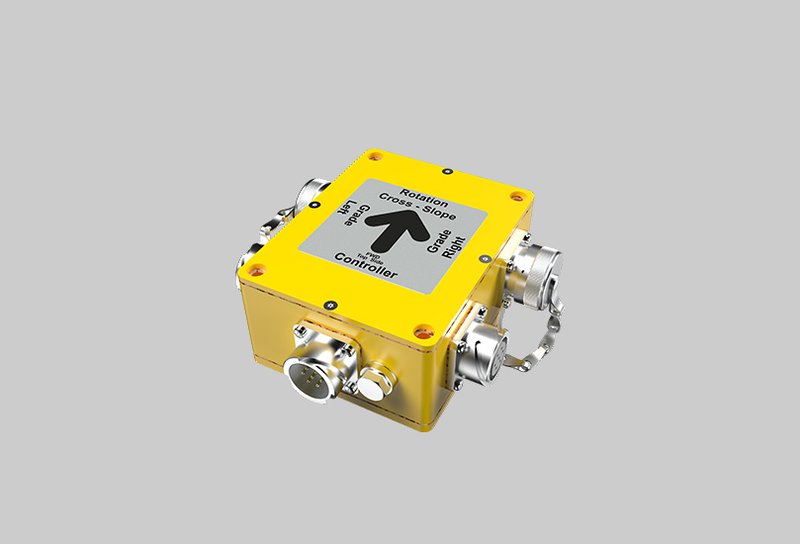

MOBA GS-506

Whether for crawler, grader, kilver or levelling blade, the 2D levelling system gives your machine a technology upgrade to eclipse all others. The system for height and inclination control regulates the coulter of your machine fully automatically so that the laid material is distributed evenly at all times. This is how the end result convinces with perfect flatness.