Boost Your Efficiency Instantly with Ultrasonic Sensor Technology

Ultrasonic sensors revolutionize automation by delivering precise distance measurements; they emit high-frequency sound waves and interpret their reflections for pinpoint accuracy.

More safety for your work basket with MOBA technology

Avoid reaching overload limits, which can happen quickly, if not monitored.

Wirelessly measure and level to ensure maximum safety.

Build with our proven systems and save on machine down time and development costs. With modular components, easily upgrade, repair, and quickly customize for specific needs.

Do you have questions about our safety solutions? We are ready to help you!

Contact Us

The patented MRW load cell allows users to avoid load limitation issues by giving exact measurements with high accuracy. No guessing or estimating. When safety is on the line, our solutions for load limitation are the best in class.

Each MRW weight cell is put through rigorous testing and is able to compensate the temperature effect on the zero point. Like a blackbox in a airplane, it stores statistical data like overload alarms, working hours, and other important data.

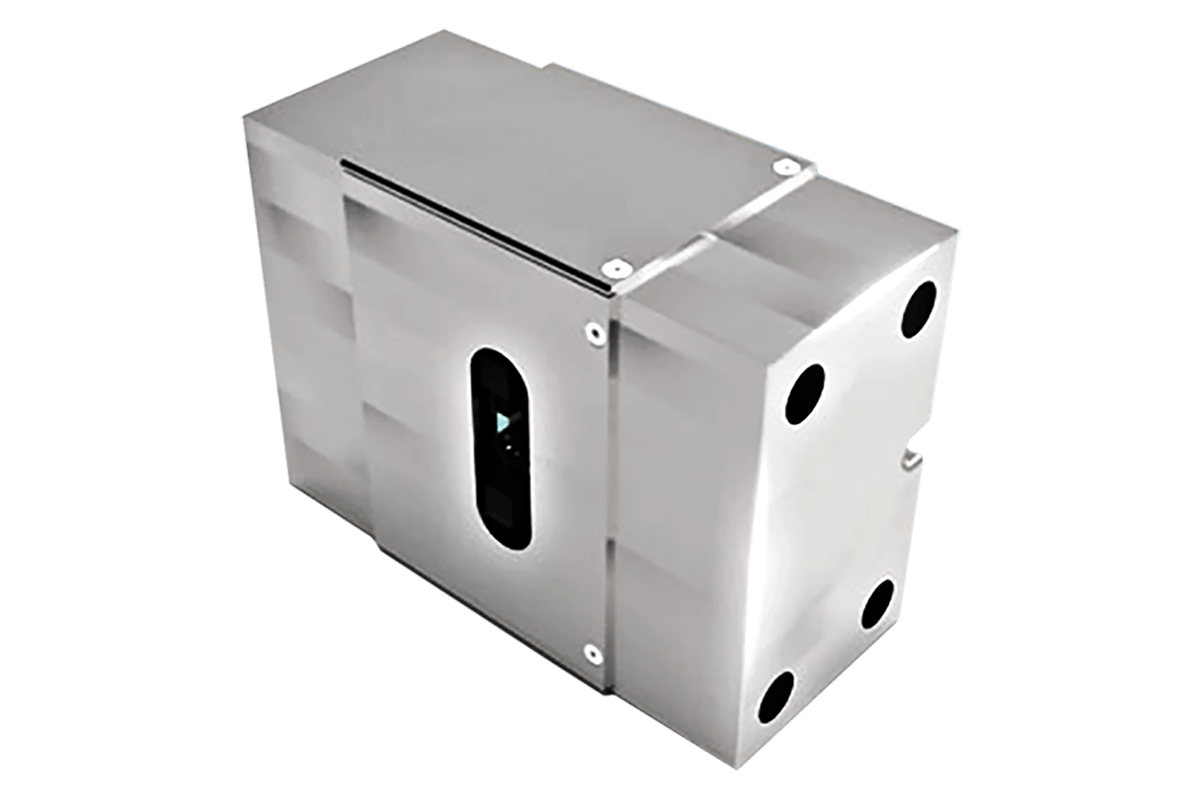

The slope sensor has been specially developed with special focus to the harsh conditions in which it is used: shock-resistant, weatherproof, with special protection against chemicals and absolutely maintenance-free.

The compact design of the tilt sensors and the different CAN interfaces are well suited for quick and easy installation on every mobile machine.

Fitted with 2 independent channels, the redundant slope sensors supply fast and accurate measured values within a range of ± 15° up to ± 180°, depending on the type.

Do you have questions about our safety solutions? We are ready to help you!

Get in touch

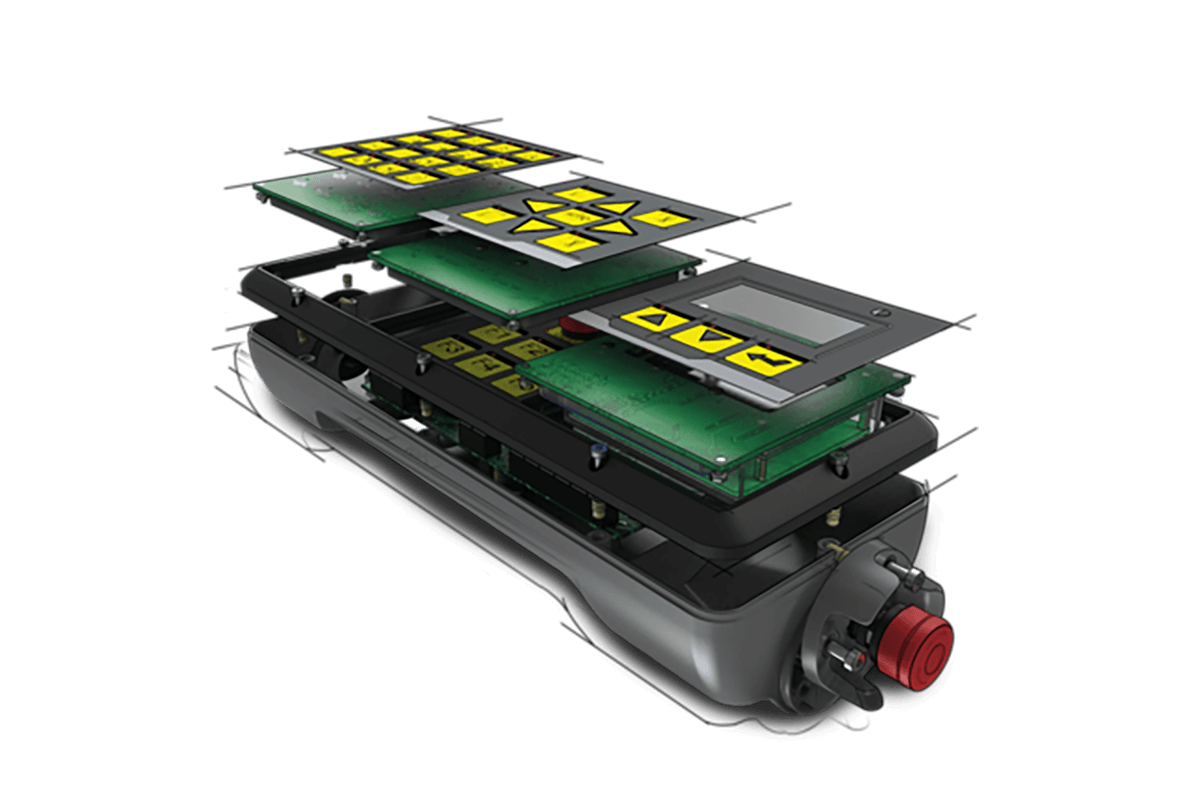

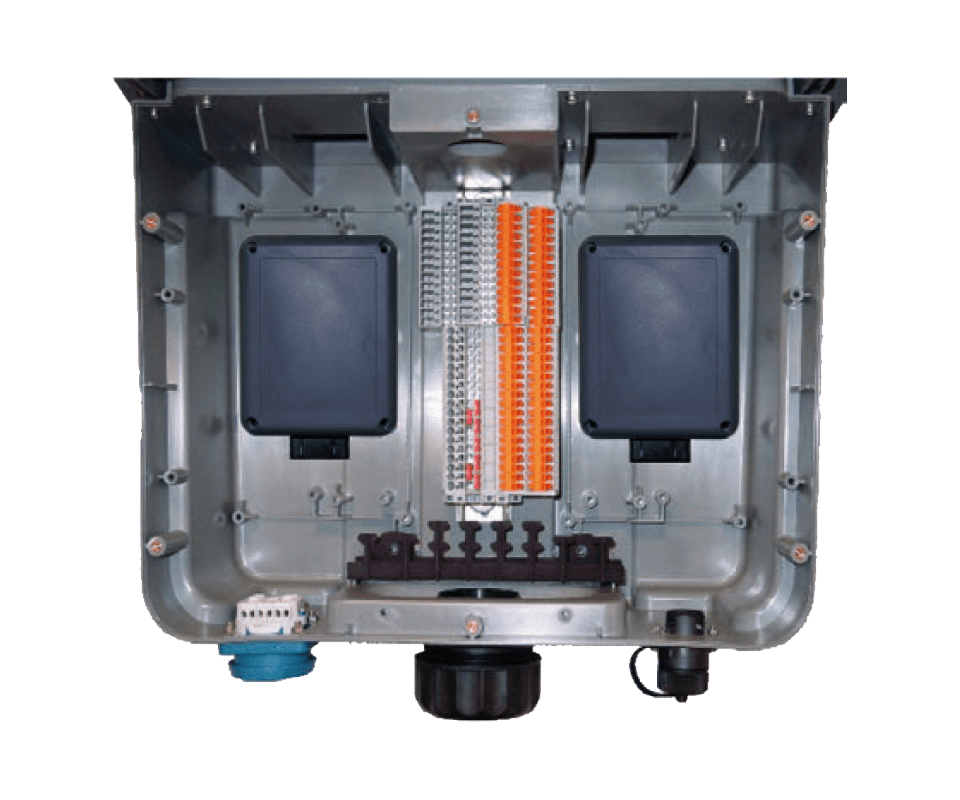

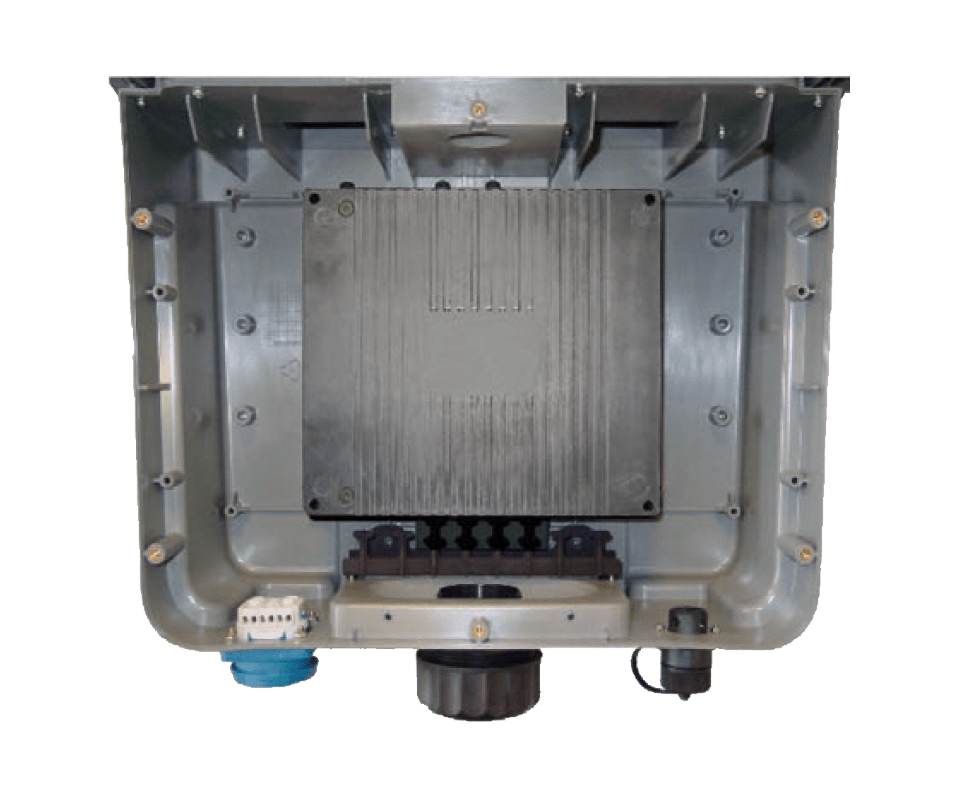

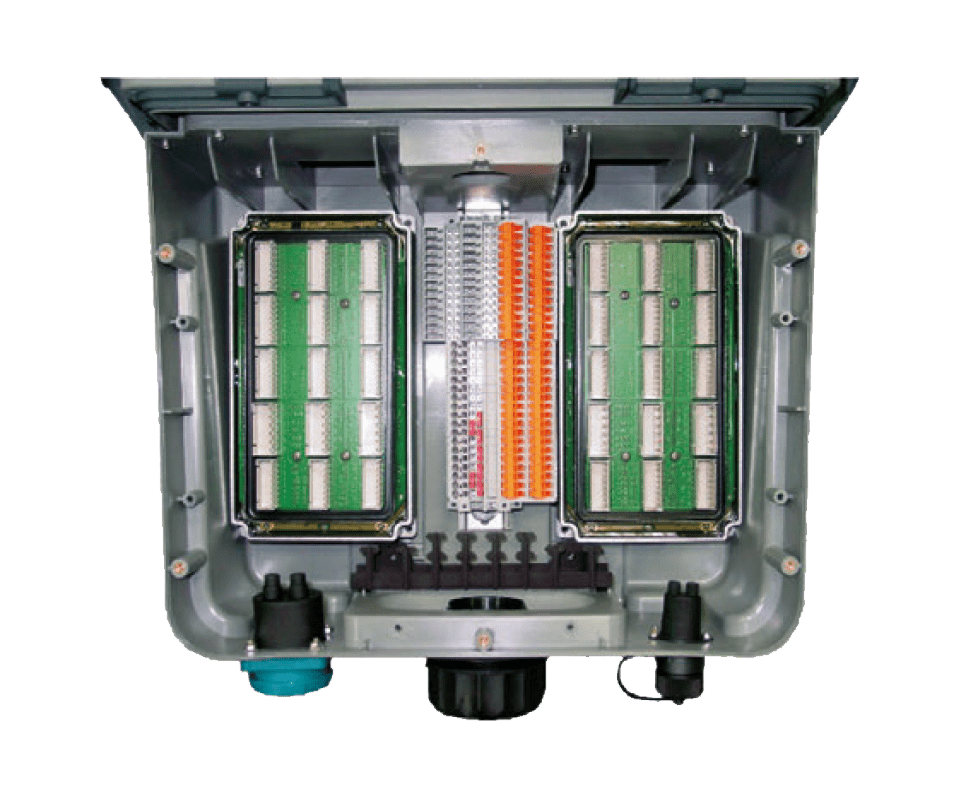

MOBA’s MCP is a true everyday hero among users thanks to its simplistic design. All components can be easily exchanged or replaced at any time. In addition to the hardware, the software has also been designed for long-term use with time-and cost efficient upgrades to increase the longevity of the system and significantly contribute to the reduction of maintenance times.

The electrical sub-distribution system integrated in the control panel eliminates the need for a switch cabinet, thus saving on additional weight, space, effort and costs.

Do you have questions about our safety solutions? We are ready to help you!

Get in touch

Ultrasonic sensors revolutionize automation by delivering precise distance measurements; they emit high-frequency sound waves and interpret their reflections for pinpoint accuracy.

From sales to service and tech support, MOBA has you covered by a highly experienced team. Meet Gary Motak and Jon Lano.

Discover MOBA’s paving technology for precision asphalt results. Visit MOBA at ConExpo 2026 in Las Vegas to see automated screed control and thermal intelligence solutions in action.

Choose Your Desired MOBA Subsidiary / Language