From sales to service, MOBA has you covered

From sales to service and tech support, MOBA has you covered by a highly experienced team. Meet Gary Motak and Jon Lano.

Avoid reaching overload limits, which can happen quickly, if not monitored.

Wirelessly measure and level to ensure maximum safety.

Build with our proven systems and save on machine down time and development costs. With modular components, easily upgrade, repair, and quickly customize for specific needs.

Do you have questions about our safety solutions? We are ready to help you!

Get in touch

The patented MRW load cell allows users to avoid load limitation issues by giving exact measurements with high accuracy. No guessing or estimating. When safety is on the line, our solutions for load limitation are the best in class.

Each MRW weight cell is put through rigorous testing and is able to compensate the temperature effect on the zero point. Like a blackbox in a airplane, it stores statistical data like overload alarms, working hours, and other important data.

The slope sensor has been specially developed with special focus to the harsh conditions in which it is used: shock-resistant, weatherproof, with special protection against chemicals and absolutely maintenance-free.

The compact design of the tilt sensors and the different CAN interfaces are well suited for quick and easy installation on every mobile machine.

Fitted with 2 independent channels, the redundant slope sensors supply fast and accurate measured values within a range of ± 15° up to ± 180°, depending on the type.

Do you have questions about our safety solutions? We are ready to help you!

Get in touch

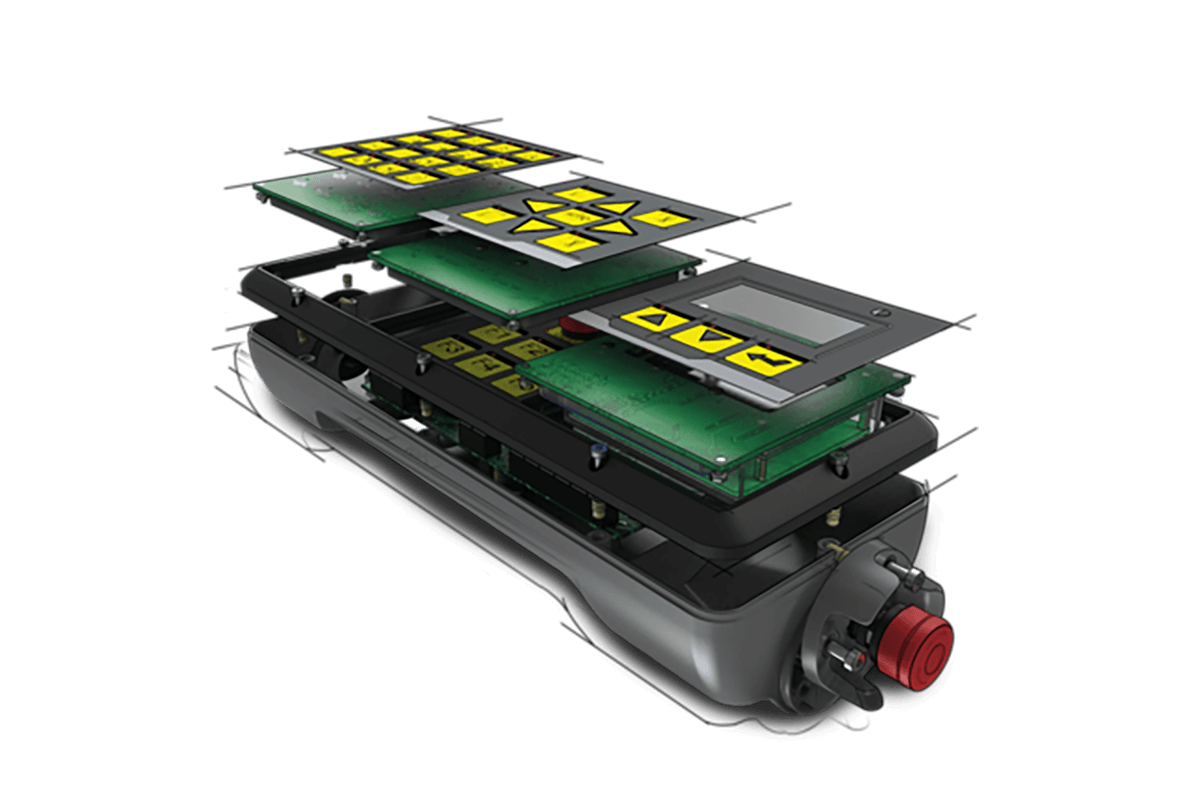

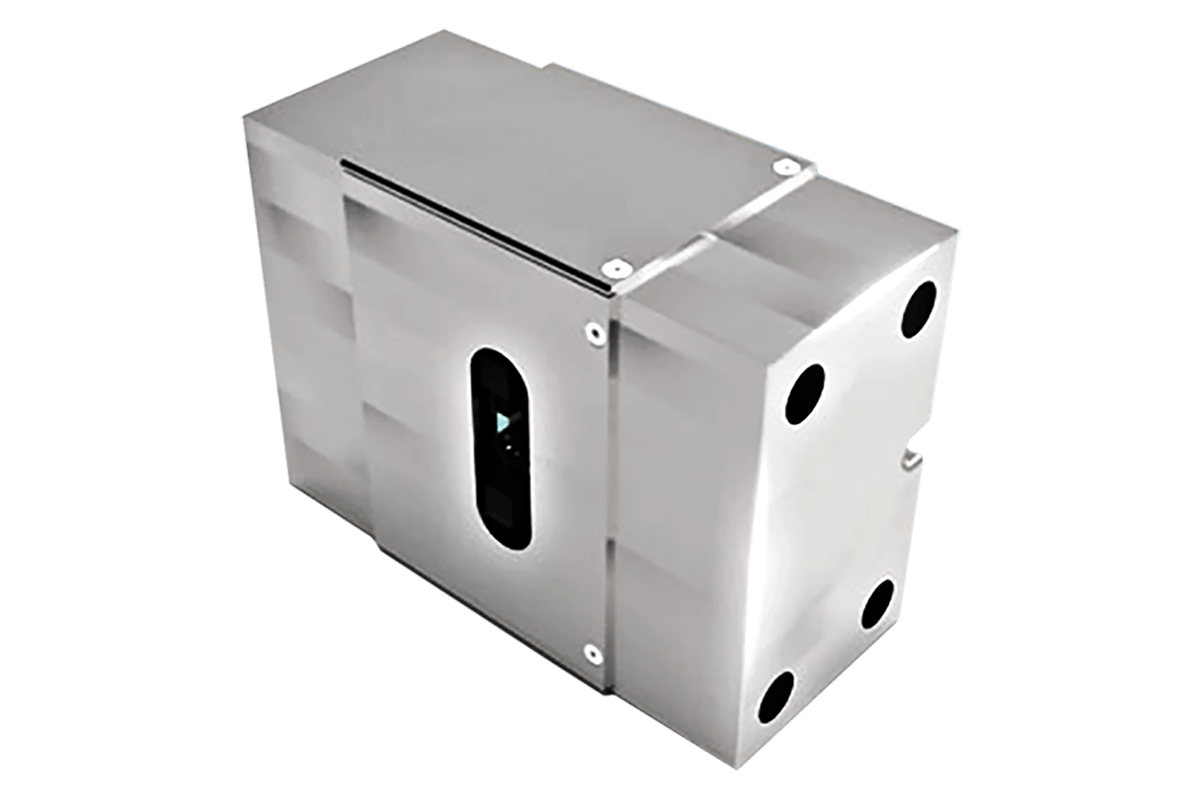

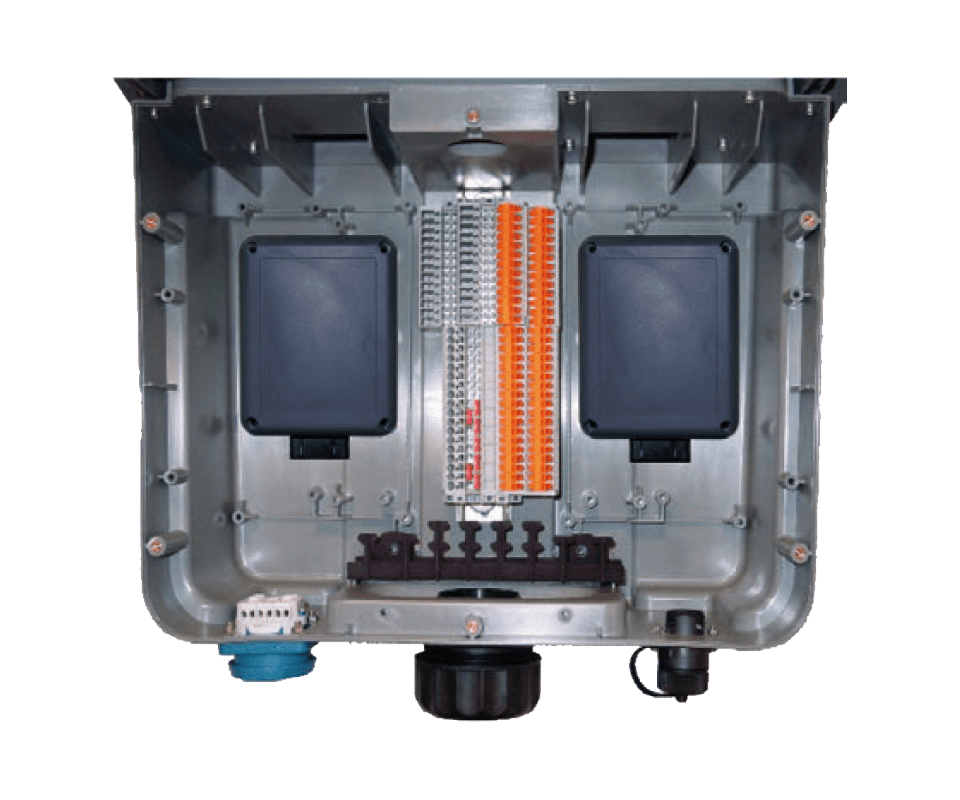

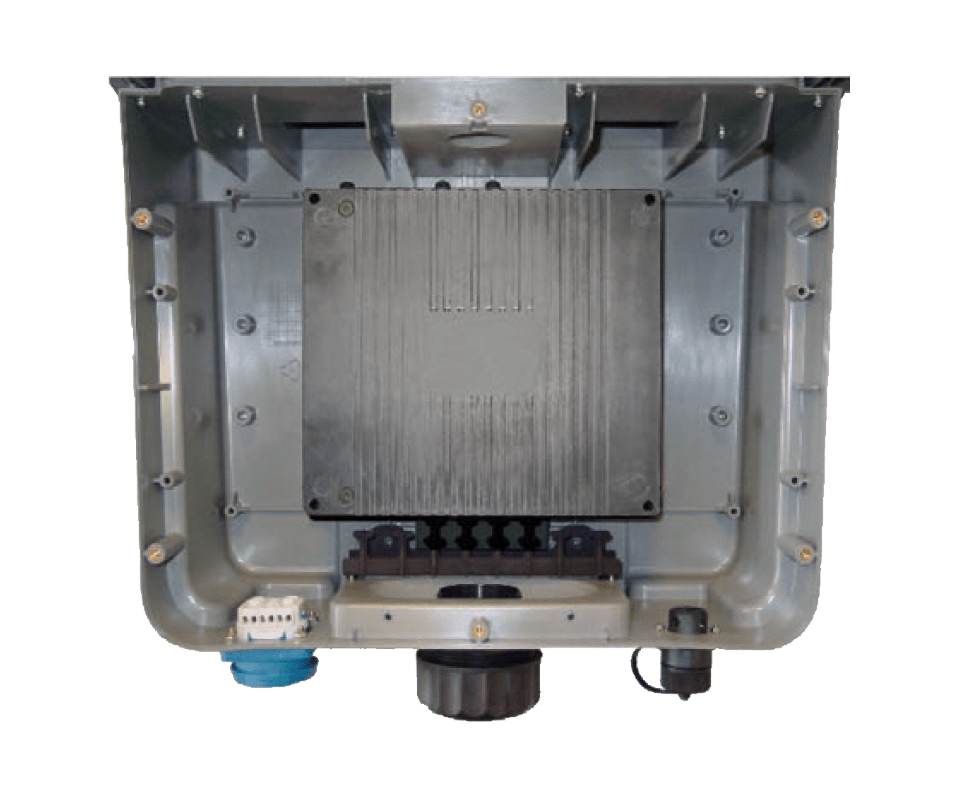

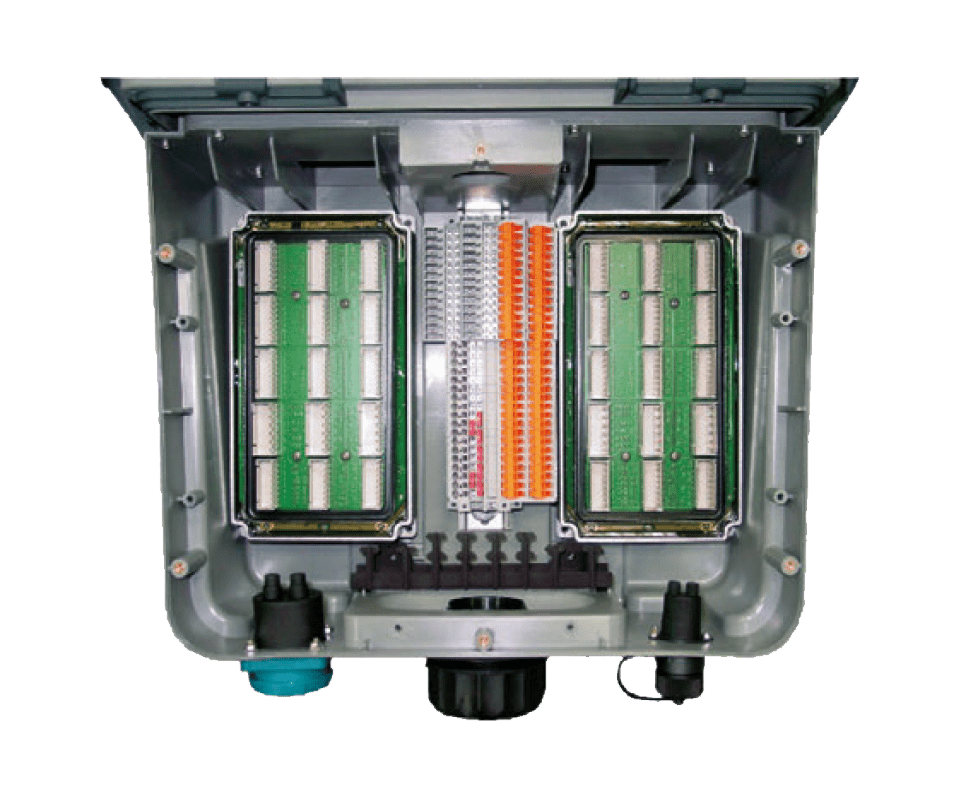

MOBA’s MCP is a true everyday hero among users thanks to its simplistic design. All components can be easily exchanged or replaced at any time. In addition to the hardware, the software has also been designed for long-term use with time-and cost efficient upgrades to increase the longevity of the system and significantly contribute to the reduction of maintenance times.

The electrical sub-distribution system integrated in the control panel eliminates the need for a switch cabinet, thus saving on additional weight, space, effort and costs.

Do you have questions about our safety solutions? We are ready to help you!

Get in touch

From sales to service and tech support, MOBA has you covered by a highly experienced team. Meet Gary Motak and Jon Lano.

The countdown is on for World of Asphalt, and MOBA is ready to showcase the industry’s most advanced paving and construction solutions. Join us at our booth to see firsthand how our technology drives efficiency, precision, and quality in road construction. MOBA has much to show from trusted systems to quality sensors and parts.

As winter approaches, efficient sand & salt application on icy roads becomes essential for municipalities, contractors, and other road safety professionals.

The first choice in mobile automation – that’s us.

More than 100 development experts and 600 employees worldwide work on a common goal every day: to sustainably change the mobile automation sector.

MOBA Corporation

1000 MOBA Drive

Peachtree City

Georgia 30269, USA

+1 (678) 817-9646 phone

+1 (678) 817-0996 fax

Choose Your Desired MOBA Subsidiary / Language

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

More information about our Cookie Policy