Next-gen technology from MOBA

Due to the rising cost of equipment operations, it is critical to reduce operating expenses and improve fleet efficiency. With an on-board scale, you will always know the exact weight of each load. This saves you both money and material, while taking full advantage of the capacity of your wheel loader and trucks.

Without mobile weighing systems, the exact weight of the material often remains unknown during loading, making time-consuming, stationary weighing necessary.

An underloaded lorry wastes your capacity. An overloaded lorry carries the risk of penalties, increases wear and tear and poses a safety risk.

Another challenge in mobile weighing technology is the collection and processing of data, the basis for good decisions.

Incl. tip-off pile and tip-off truck modes

As well as target weighing function

For further analysis

And large touch display

To minimize downtimes

And multi-language support

Purchase this out-of-the-box solution today!

Purchase

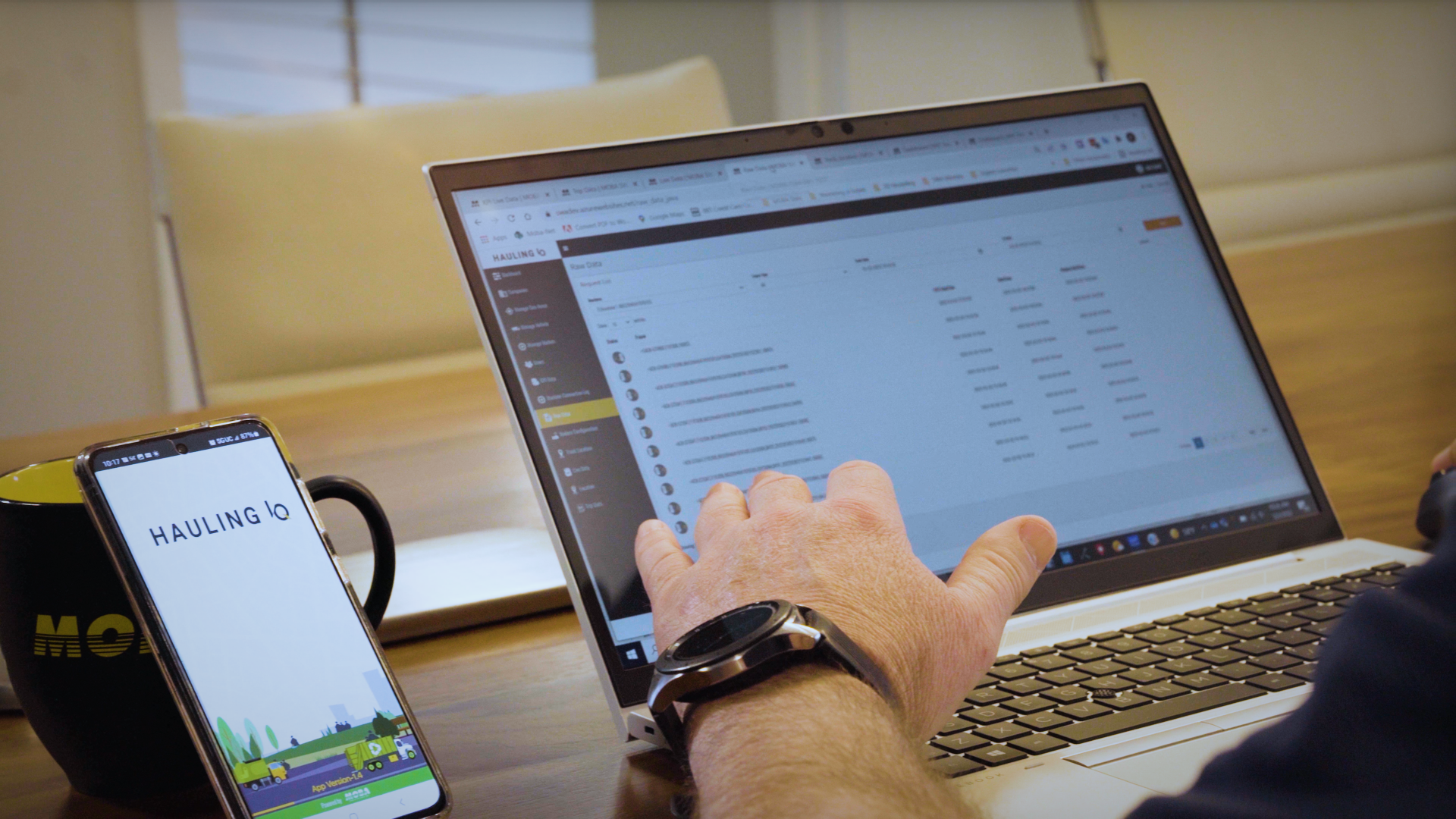

A web-based software platform provides a user-friendly monitoring system for all your vehicles. Hauling IQ provides a clean, comprehensive and intuitive design to track and segment fleet data.

Search, Sort, Export, Print, Email

Filter data by date/time, Machine, Data field, Export/Print

Today, Week, Month, Year

Track your assets in real time

2D MEASURING AND CONTROL SYSTEM

2D MEASURING AND CONTROL SYSTEM

2D MEASURING AND CONTROL SYSTEM

With our system, every load can be dynamically measured in real time to prevent overloading and underloading, and is a productivity boost for anyone in the world of waste management or hauling.

One such example: a major metropolitan waste company in Florida generated $132,313 in annual savings just by installing MOBA’s HLC system on two of their loaders.

Our case study analyzed the site’s operations, which operated the handling and loading of bulk waste materials. The site ran at 8-hour shifts each day, alternating between two wheel loaders, with a target weight of 24 tons per load (850 tons per day). With our system, the client discovered their loaders were only achieving about 16 tons per load, well below their goal. This lack of visibility translated into significant underloading, overusing of the truck fleet, and ultimately wasting time and money.

Once the HLC-1000 Wheel Loader scales were installed and the operators trained to maximize each load, the overall load average increased from 16 tons to approximately 23.5 tons per load. Additionally, the operators optimized their time with each load by getting the amount almost exactly right the first time, every time. That meant the site saw considerable savings and improved operations.

Because of MOBA, this site is now much safer, more productive and more profitable: a major improvement that paid for itself within a month.

Choose Your Desired MOBA Subsidiary / Language