Automated Screed Control for Asphalt Paving

Asphalt paving is a crucial component of infrastructure development, and achieving a smooth, even surface is essential for ensuring road safety and longevity. Automated screed control systems have emerged as a game-changer in the paving industry, offering enhanced precision and efficiency. In this article, we will explore the importance of automated screed control for asphalt paving, its influence on International Roughness Index (IRI) scores, and how it can benefit paving contractors.

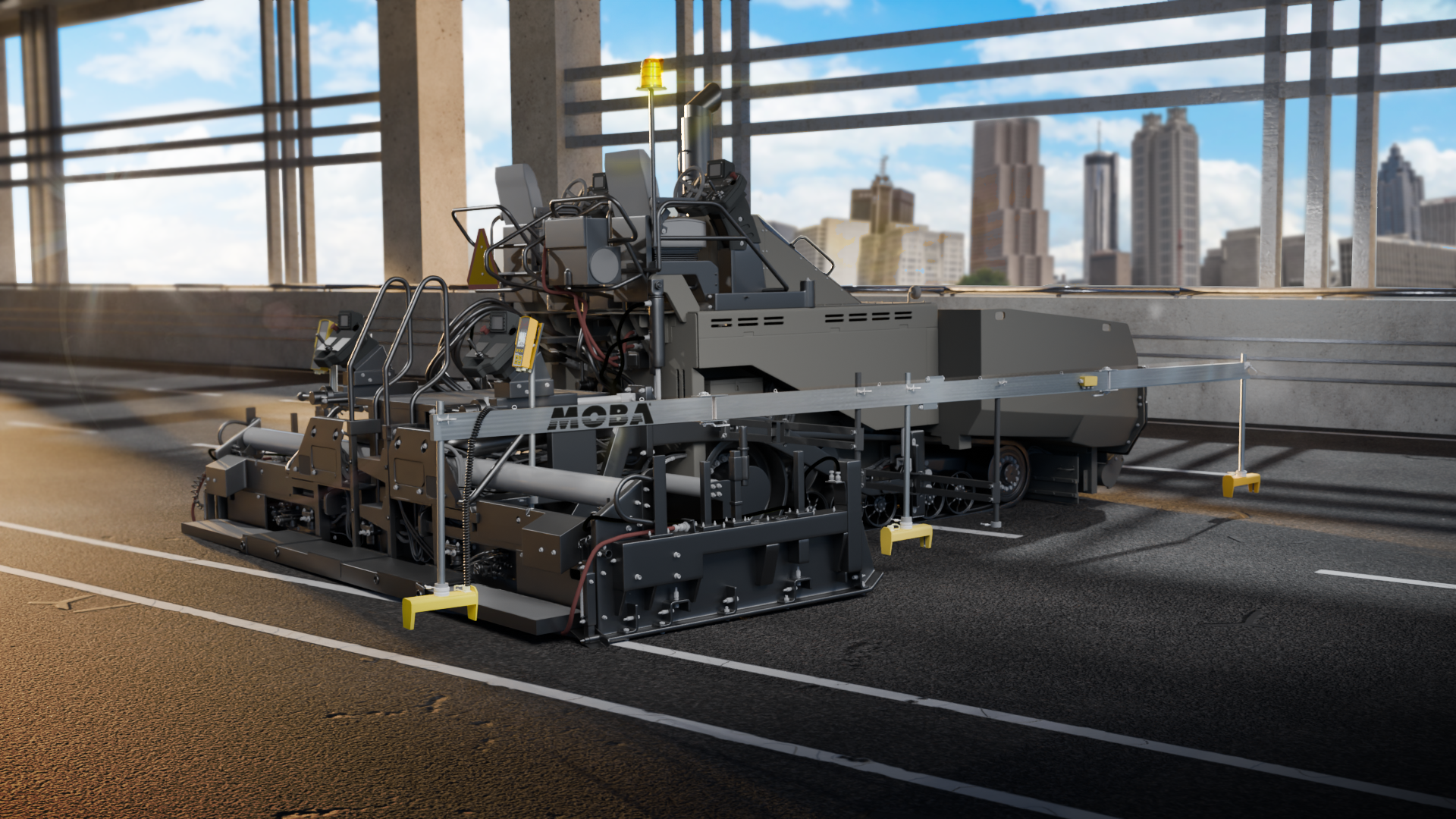

Automated screed control systems are advanced technologies designed to optimize the paving process. These systems utilize sensors and software to automatically adjust the screed’s height and angle, ensuring a consistent and level asphalt surface. By reducing human error and manual adjustments, automated screed control contributes to better paving smoothness and improved IRI scores.

- Sensors: These devices monitor the screed’s position and the surface being paved. They provide real-time data to the control system.

- Control Unit: This is the brain of the system, processing data from sensors and making necessary adjustments to the screed.

- Actuators: These mechanical components execute the adjustments dictated by the control unit, altering the screed’s position as needed.

The International Roughness Index (IRI) is a standard measure of road smoothness. Lower IRI scores indicate a smoother road, which translates to enhanced driving comfort, reduced vehicle wear and tear, and increased safety. Automated screed control systems significantly contribute to achieving better IRI scores by ensuring consistent pavement quality.

- Precision: Automated systems provide precise control over screed adjustments, reducing surface irregularities and achieving a smoother finish.

- Consistency: By minimizing human intervention, these systems ensure a uniform paving process, resulting in consistent surface quality.

- Efficiency: Automated screed control allows for faster paving, reducing the likelihood of errors and rework.

MOBA-MATIC II IN DETAIL

Paving contractors can significantly benefit from the adoption of automated screed control systems. Here’s how:

One of the primary benefits of automated screed control is the improved paving smoothness. By maintaining a consistent asphalt layer, contractors can deliver higher-quality roads that meet or exceed industry standards.

With automated systems handling screed adjustments, contractors can focus on other critical aspects of the paving process. This increased efficiency results in faster project completion and lower labor costs.

As the industry moves towards automation, contractors who adopt these technologies early gain a competitive advantage. Offering superior paving quality and faster project delivery can help secure more contracts and build a strong reputation.

While the initial investment in automated screed control systems may be higher, the long-term cost savings are substantial. Reduced rework, lower labor costs, and enhanced project efficiency contribute to a more profitable operation.

Moba-Matic is a renowned name in the field of screed control technology. Their systems are designed to provide precise control over asphalt paving, ensuring optimal paving smoothness and better IRI scores. Here’s what sets Moba-Matic apart:

Moba-Matic systems feature an intuitive interface, making it easy for operators to monitor and control the paving process. The user-friendly design reduces the learning curve, allowing for seamless integration into existing workflows.

With the optional MM-View Remote Diagnostic tool, you can avoid extended machine downtime and costly service visits. Our service experts are able to make direct changes to your controller and machine in seconds.

These systems are compatible with a wide range of paving machines, making them a versatile choice for contractors. Whether you’re working on a small residential project or a large highway, Moba-Matic systems can meet your needs.

Moba-Matic offers real-time monitoring capabilities, allowing operators to make adjustments on the fly. This feature ensures that paving quality is maintained throughout the project, resulting in better IRI scores and overall satisfaction.

As technology continues to advance, the paving industry is set to benefit from even more innovative solutions. Automated screed control is just the beginning. Future developments may include fully autonomous paving machines, which will further enhance efficiency and precision.

For paving contractors, embracing automation and advanced technologies is crucial for staying competitive. By investing in systems like automated screed control, contractors can ensure they are at the forefront of industry advancements, ready to meet the demands of modern infrastructure projects.

Automated screed control systems represent a significant advancement in the asphalt paving industry. By enhancing paving smoothness, improving IRI scores, and increasing efficiency, these systems offer substantial benefits to paving contractors. As leaders in screed control technology, companies like Moba-Matic are paving the way for a more automated and efficient future. Contractors who embrace these innovations will be well-positioned to thrive in the evolving landscape of infrastructure development.

Incorporating automated screed control into your paving operations can lead to better quality roads, satisfied clients, and a more prosperous business. As the industry continues to evolve, staying informed and adopting new technologies will be key to success.

Learn more about Moba-Matic and download our digital brochure today!