See MOBA’s Proven Paving Technology Live at ConExpo‑Con/Agg

When it comes to asphalt paving, consistency, smoothness, and thermal control aren’t optional—they’re what separate profitable jobs from costly rework. At ConExpo, MOBA will showcase the paving technologies trusted by contractors and OEMs worldwide to deliver better mats, tighter tolerances, and measurable results on every pass.

If you’re looking for field-proven systems that crews rely on day after day, these are the solutions you’ll want to see firsthand.

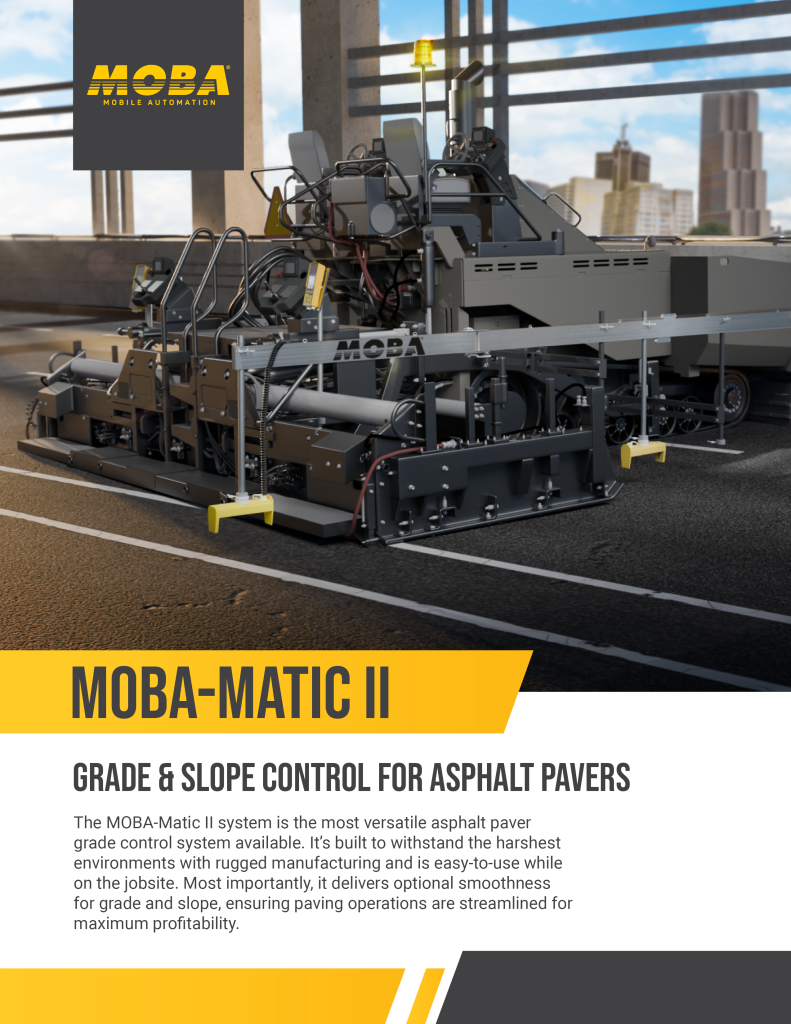

MOBA-Matic — The Industry Standard for Automatic Screed Control

MOBA-Matic remains MOBA’s best-selling paving system for a reason. Designed to automatically control screed height and slope, MOBA-Matic helps crews achieve consistent mat thickness while reducing operator workload and variability.

Contractors choose MOBA-Matic because it:

- Delivers reliable grade and slope control in real-world paving conditions

- Reduces over- and under-paving to save material

- Improves ride quality and spec compliance

- Works seamlessly with MOBA’s sensor portfolio

Whether you’re paving highways, city streets, or commercial lots, MOBA-Matic provides the control crews trust when quality matters most.

MM-View — Remote Support When and Where You Need It

Downtime costs money. MM-View gives contractors and service teams the ability to remotely access MOBA systems for diagnostics, support, and troubleshooting—without waiting for someone to arrive on site.

With MM-View, users can:

- Receive faster technical support

- Reduce jobsite delays and service costs

- Diagnose issues remotely with MOBA experts

- Keep machines productive during tight paving windows

At ConExpo, you’ll see how MM-View helps keep projects moving and crews supported—even when they’re miles apart.

Sonic Ski® — Smoothness Control That Sets the Standard

Sonic Ski is MOBA’s long-range, non-contact averaging system designed to deliver superior smoothness over varying surfaces. By averaging surface irregularities, Sonic Ski helps eliminate dips, bumps, and transitions that short sensors can’t compensate for.

Key benefits include:

- Improved IRI and overall ride quality

- Consistent results over bridges, milled surfaces, and variable base

- Non-contact operation for reliable performance in tough conditions

- For contractors focused on smoothness specs and long-term performance, Sonic Ski remains one of the most effective tools on the paver.

PAVE-IR® — Real-Time Thermal Intelligence for Asphalt Quality

Temperature segregation is one of the leading causes of premature pavement failure. PAVE-IR provides real-time thermal mapping behind the screed, allowing crews to identify cold spots immediately and take corrective action before compaction.

With PAVE-IR, contractors can:

- Visually monitor mat temperatures in real time

- Document thermal consistency for quality assurance

- Reduce segregation-related defects

- Improve pavement longevity and performance

At ConExpo, MOBA will demonstrate how PAVE-IR turns temperature data into actionable insight directly on the jobsite.

See MOBA’s Paving Solutions in Action at ConExpo

MOBA’s paving technologies aren’t experimental, they’re field-proven, contractor-trusted, and OEM-validated. At ConExpo, you’ll have the opportunity to see these systems up close, ask technical questions, and learn how MOBA solutions work together to improve paving accuracy, efficiency, and quality.

If you’re serious about delivering better asphalt results, make sure MOBA is on your ConExpo list.