MOBA Excavator Control Systems

2D and 3D excavator control systems: optimal for every construction site

Challenges in excavation work

Exact Depth

During Excavation the driver can only assume the correct depth. To verify the depth needs to be checked manually.

High operating costs

Manual measurement causes high operating costs and requires a lot of time.

Safety

The surveyor who measures the depth manually has to move into a risk zone.

COMPLEX DESIGN

Creating surfaces with multiple slope changes requires even more manual checks.

Inclination

The operator can only visually duplicate previous slopes and then manually check them.

EXPERIENCE

If the operator has not enough experience it will be difficult to get a good result.

MOBA Excavator Control Systems

Xsite EASY

IDEAL IMPLEMENTATION OF SIMPLE EARTHWORKS

Our robust Xsite EASY ideally equips you for the daily construction routine. Harsh weather conditions, rough terrain or poor visibility do not pose a challenge any more. The excavation system allows you to maintain the correct perspective. The system is ideally suited for foundation construction, excavation or embankment construction, or for leveling or under water excavation.

Easy to operate

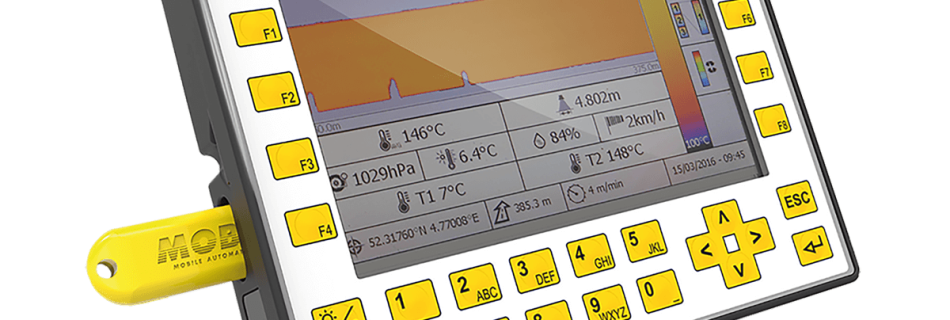

The precise bucket position is shown to the operator graphically and numerically on the display in real time. This information enables the machine operator to know the exact position and progress of the work at any time. The operator can work exactly according to plan and meet the requirements exactly and fast.

LASER AS REFERENCE

The system’s laser receiver enables moving your machine at the site without losing the original level.

Upgradeable

Thanks to the CAN-based development of further hardware components focused on system modularity, the system can be upgraded from 2D to 3D functionality in a very short time and cost-efficiently. Invest in this modular system to keep all its features accessible and increase your ROI.

Get the most out of your machine with Xsite Easy

Do you have questions about our excavator control? We are ready to help you!

Contact Us

prepared for every construction site

Xsite PRO 2D

new opportunities for the construction site of the future

With the Xsite® PRO 2D system you are always well equipped for all requirements of a construction site. Whether simple work or complex construction projects, MOBA excavator controls provide a perfect interaction between all components to provide a precise, efficient result. Thanks to the modular structure of the 3D software, Xsite PRO can also be upgraded at any time. The Xsite® PRO system enables the smooth handling of network correction services, base stations and GNSS receivers from different manufacturers. This eliminates single manufacturer commitment and allows you to work on multiple projects without the risk of incompatibility. In addition, the system is compatible with third-party software such as BIM cloud providers. Different openBIM data formats can be used without conversion or compatibility problems. This gives you a significant market leadership position in a competitive market.

Easy to operate

The precise bucket position is shown to the operator graphically and numerically on the display in real time. This information enables the machine operator to know the exact position and progress of the work at any time. The operator can work exactly according to plan and meet the requirements exactly and fast.

Remote Support

With remote support, your local reseller can provide you with guidance without having to visit the site. Remote support connects your system to the service centre and can be used to offer training, advice or troubleshooting.

Upgradeable

Thanks to the CAN-based development of further hardware components focused on system modularity, the system can be upgraded from 2D to 3D functionality in a very short time and cost-efficiently. Invest in this modular system to keep all its features accessible and increase your ROI.

Xsite PRO 3D

High-end 3D excavator control for optimal excavation work

Easy to operate

The precise bucket position is shown to the operator graphically and numerically on the display in real time. This information enables the machine operator to know the exact position and progress of the work at any time. The operator can work exactly according to plan and meet the requirements exactly and fast.

Remote Support

With remote support, your local reseller can provide you with guidance without having to visit the site. Remote support connects your system to the service centre and can be used to offer training, advice or troubleshooting.

LIVE UPLOAD

Compatible with third-party cloud solutions such as file transfer and fleet management. If required, wireless data transfer also allows preparing the data from the office, whether for further development, documentation or support purposes.

EARTHMOVING

GLOBAL DISTRIBUTION & LOCAL SERVICE

In addition to our US headquarters, MOBA is represented by its subsidiaries in Europe, South America, India, Asia and Australia, and by a worldwide dealer network in all key markets in the sectors it serves.

Our latest blog posts on Excavator control systems

Maximizing Winter Operations with A Salt Management System from MOBA

As winter approaches, efficient sand & salt application on icy roads becomes essential for municipalities, contractors, and other road safety professionals.

iVT Chicago 2025 post-show recap and insights from MOBA

If you’re looking to streamline your next equipment build, reduce integration headaches, and deliver future-ready functionality to your customers, MOBA is the name you can trust.

Why MOBA is the Top Choice for OEMs and System Integrators in Construction and Beyond

If you’re looking to streamline your next equipment build, reduce integration headaches, and deliver future-ready functionality to your customers, MOBA is the name you can trust.