Xsite® EASY

Xsite® EASY helps you save time on site with straightforward, reliable operator guidance.

Challenges in excavation work

For many small companies and single-machine operators, precision work often means relying on manual checks, stakes, or repeated measurements. This slows down the job, increases the risk of errors, and costs valuable time and resources.

Unnecessary rework due to inaccurate digging

Dependence on external surveyors or grade checkers

Time-consuming manual measuring and checking

Difficulties keeping productivity high with limited resources

Xsite® EASY

Your first step into machine control.

Xsite EASY is designed for operators who want a simple, reliable way to improve excavation accuracy without complexity. With an intuitive touchscreen and clear real-time guidance, the system shows exactly where the bucket is — helping you get the job done faster, smarter, and with confidence.

Work faster and more accurately

Easy-to-use operator guidance helps you get the job done right the first time.

Boost productivity and cut costs

Intuitive operation reduces downtime and eliminates unnecessary rework.

Straightforward and reliable

Clear in-cab guidance makes excavation easier, even without specialist knowledge.

Simplicity meets precision

A practical system that combines ease of use with professional accuracy.

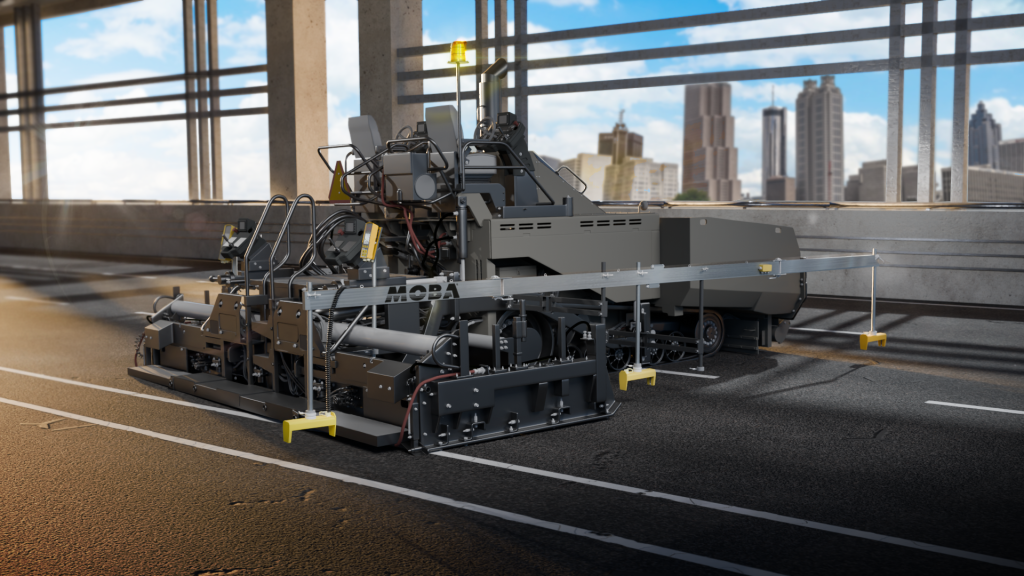

Get the most out of your machines with MOBA Systems

Do you have questions about our solutions? We are ready to help you!

Contact us

Simple Excavator Control for Small Projects

Xsite® EASY Application Areas

Perfect for smaller jobs and everyday projects

- Landscaping and garden construction

- Utility and pipeline trenching

- House foundations and small building projects

- Agricultural and municipal works

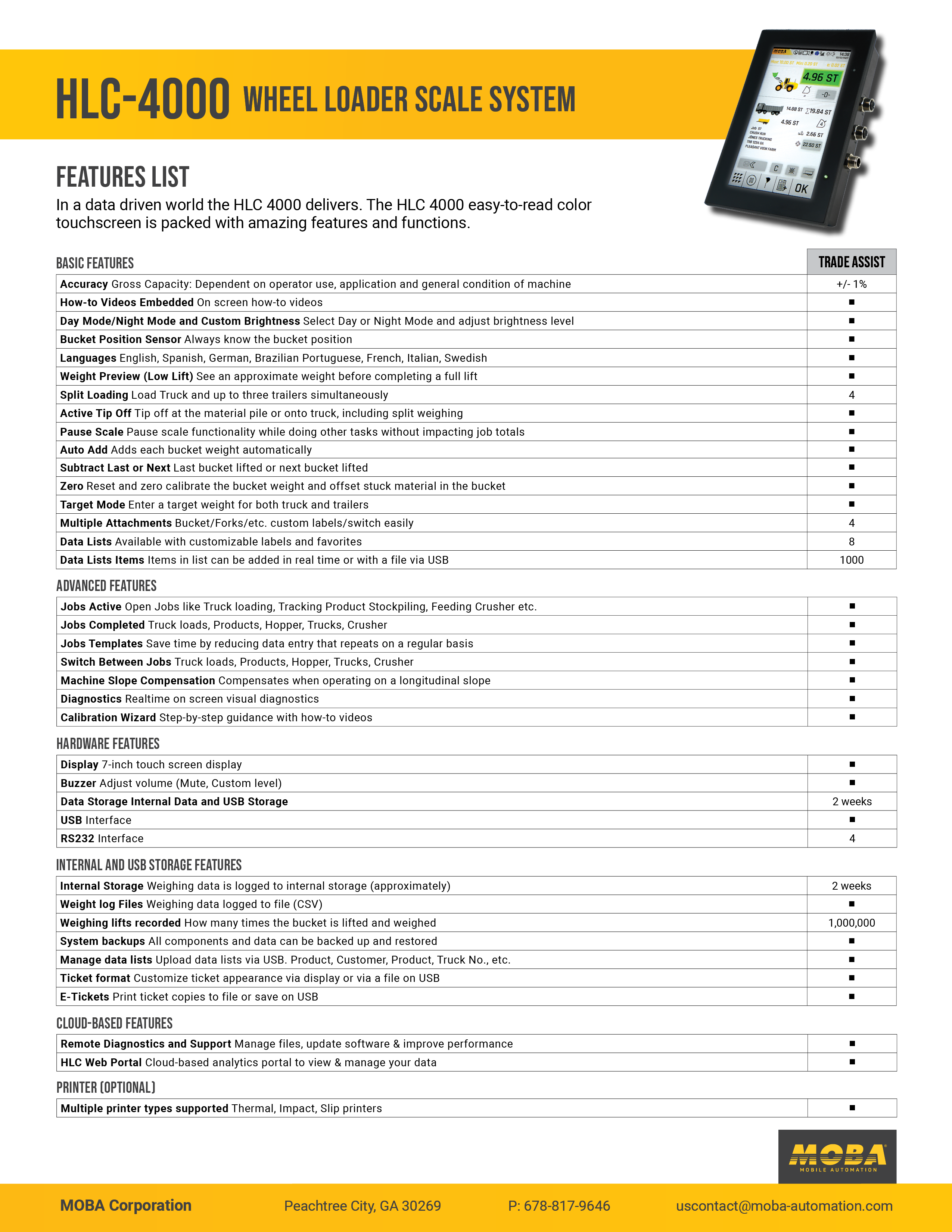

Xsite® EASY Features

Compact technology with powerful benefits

Xsite EASY combines practical functionality with a user-friendly design that fits the needs of smaller businesses.

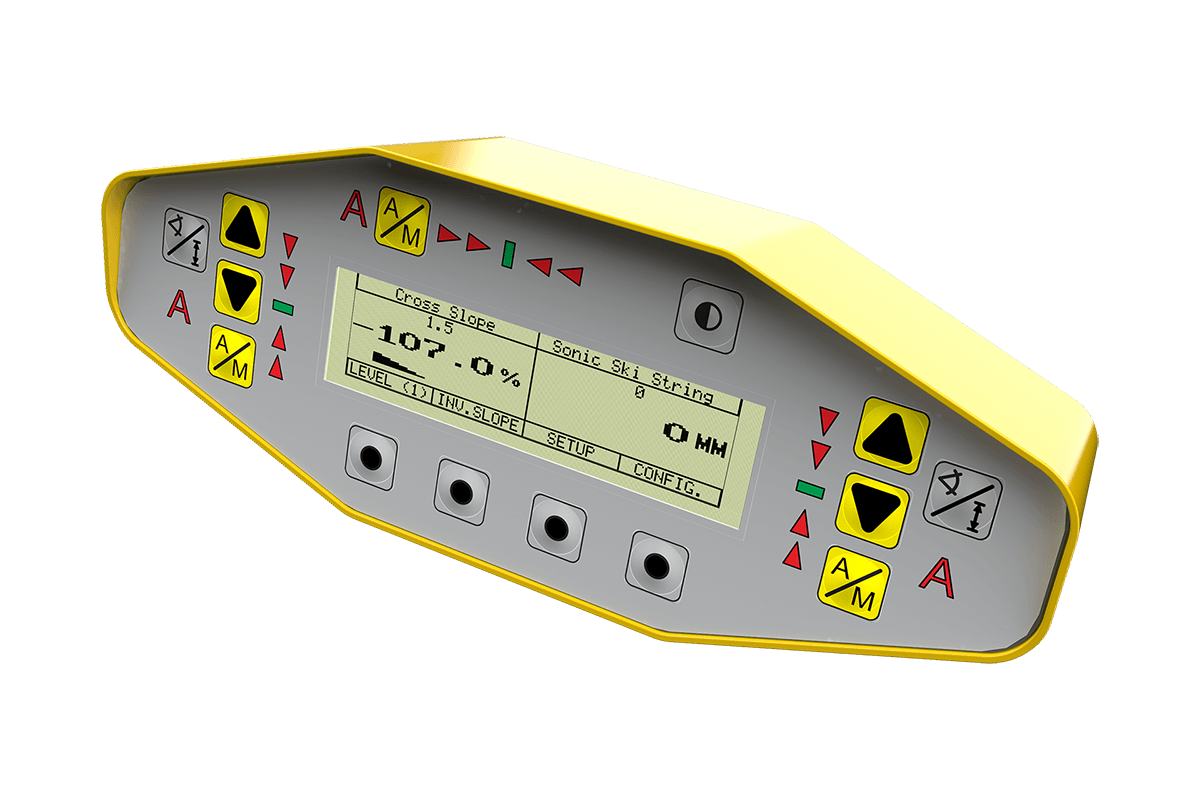

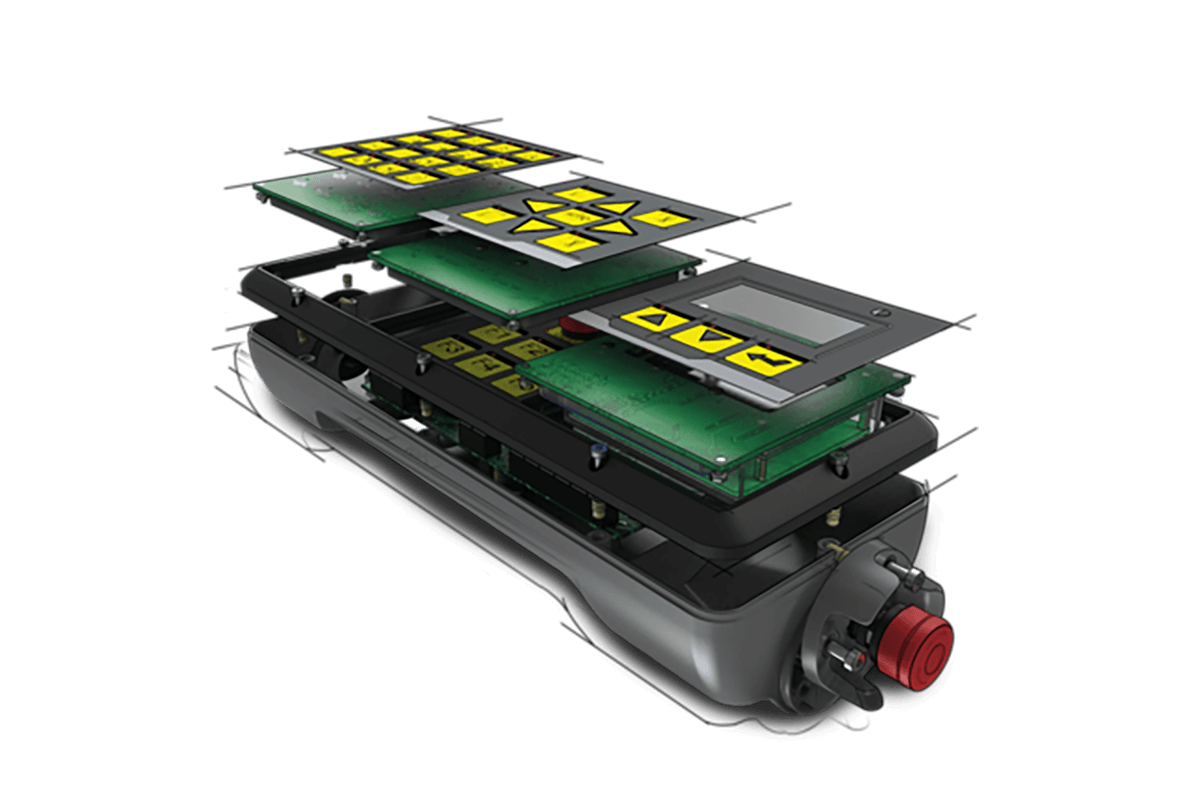

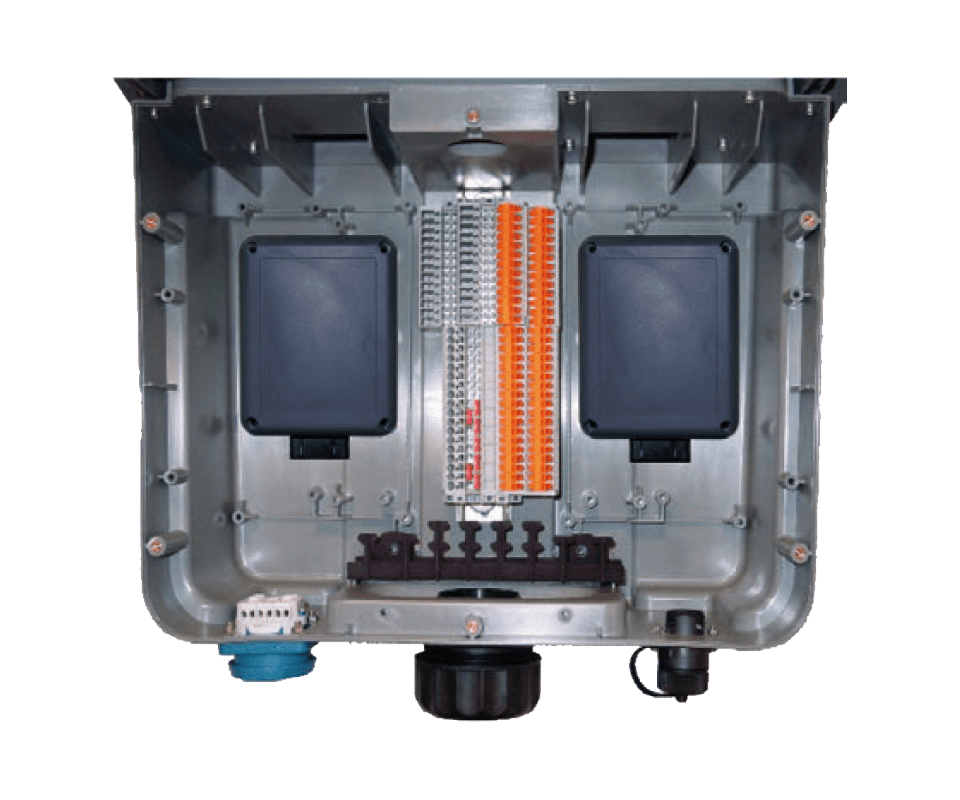

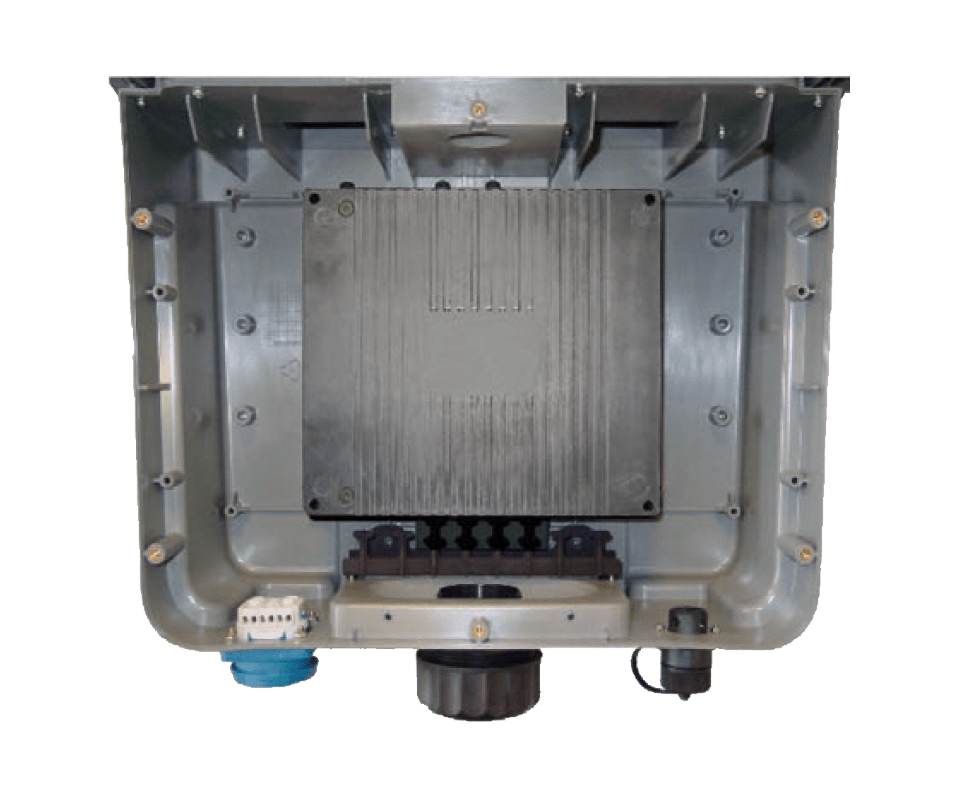

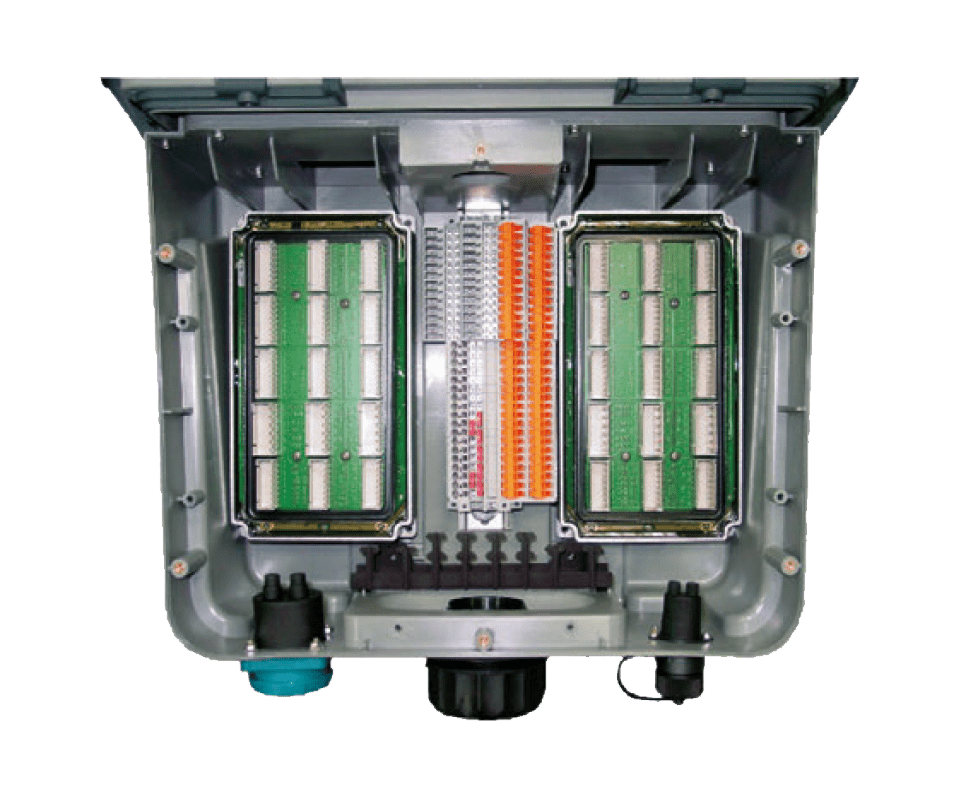

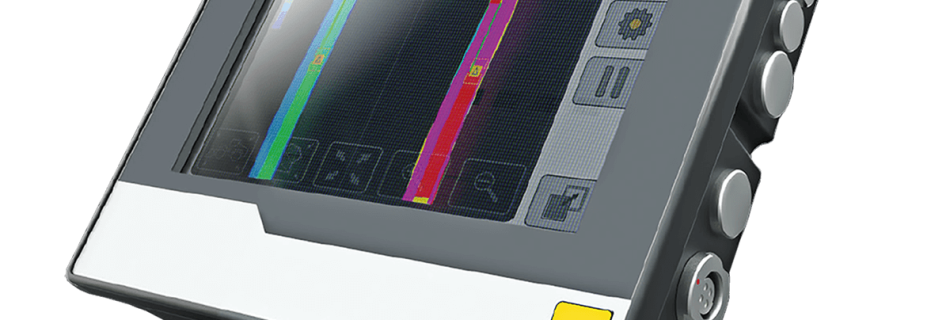

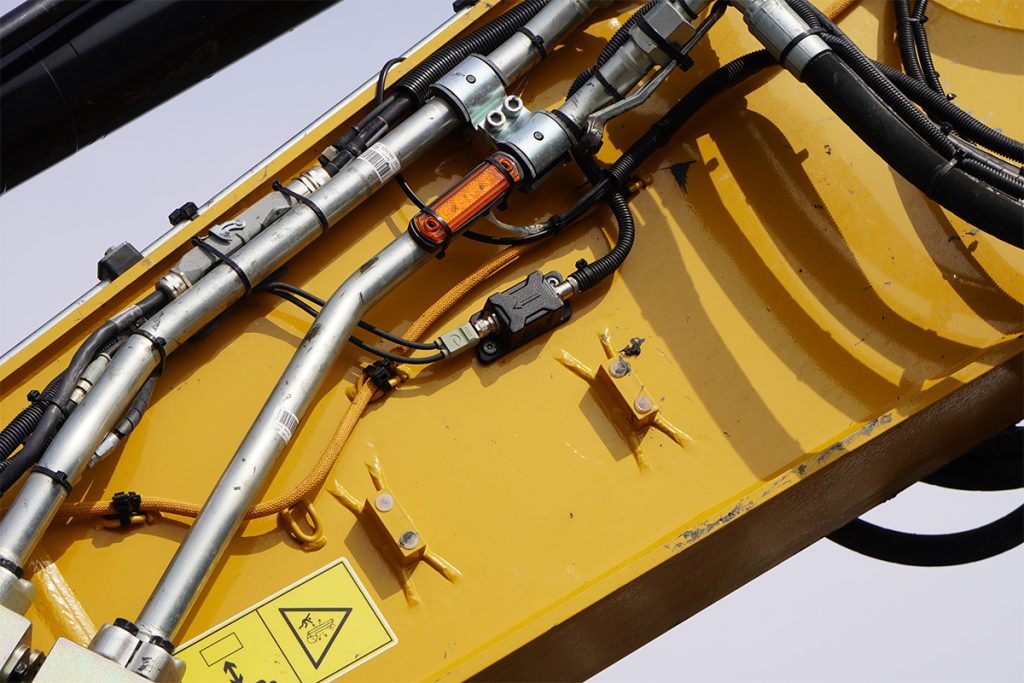

The system uses durable angle, tilt, and rotation sensors that continuously measure the excavator’s movements. These values are processed in real time by the control unit and shown on the in-cab display. Thanks to CAN-bus communication and robust sensor housings, Xsite EASY ensures accurate results and long-term reliability, even in tough working conditions.

Real-time bucket position

See depth, height, and slope instantly on the display.

Simple touchscreen interface

Clear visuals and intuitive controls for everyday use.

Straightforward and reliable

Durable sensors and robust design ensure long-term accuracy.

Save time on site

Reduce the need for manual checks and repeated measuring.

Improve work quality

Achieve consistent results with less risk of rework.

Upgradeable platform

Grow with your projects by upgrading to Xsite PRO systems.

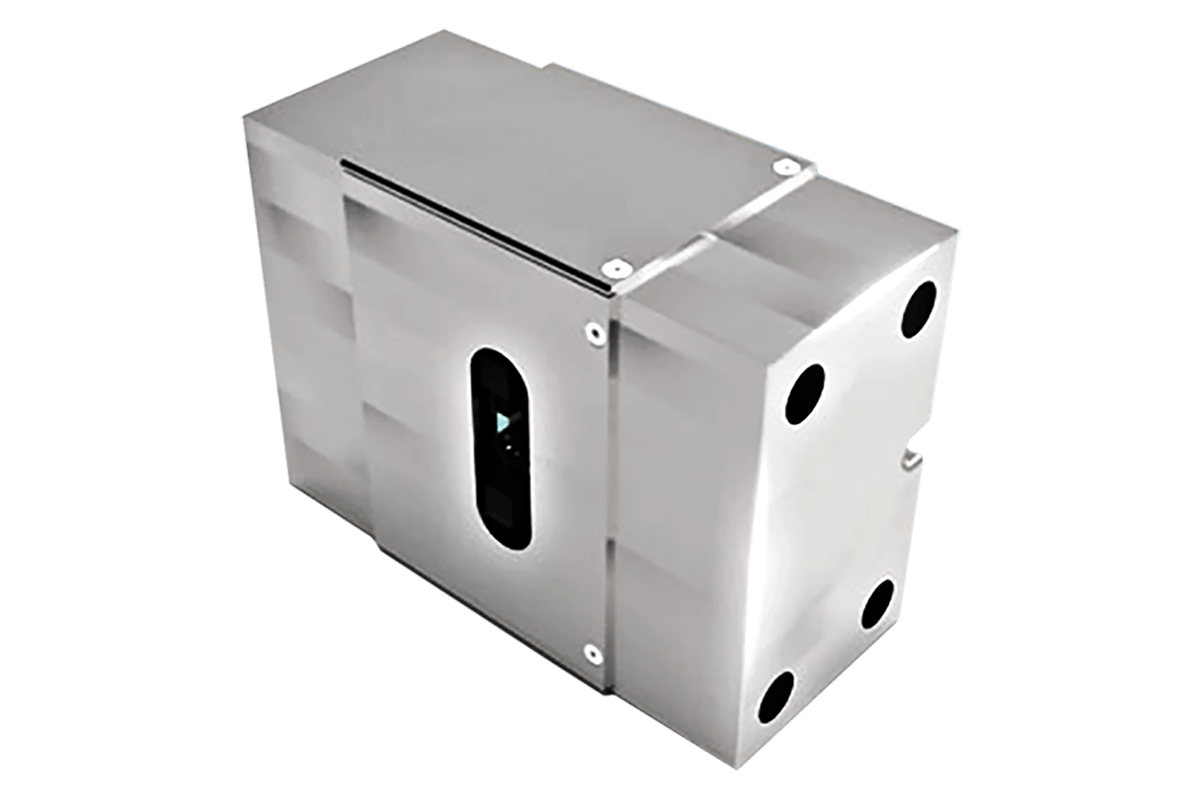

Xsite® EASY components

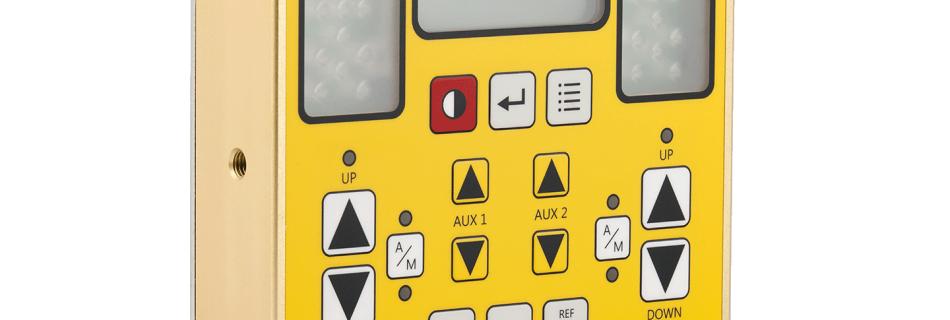

Display unit

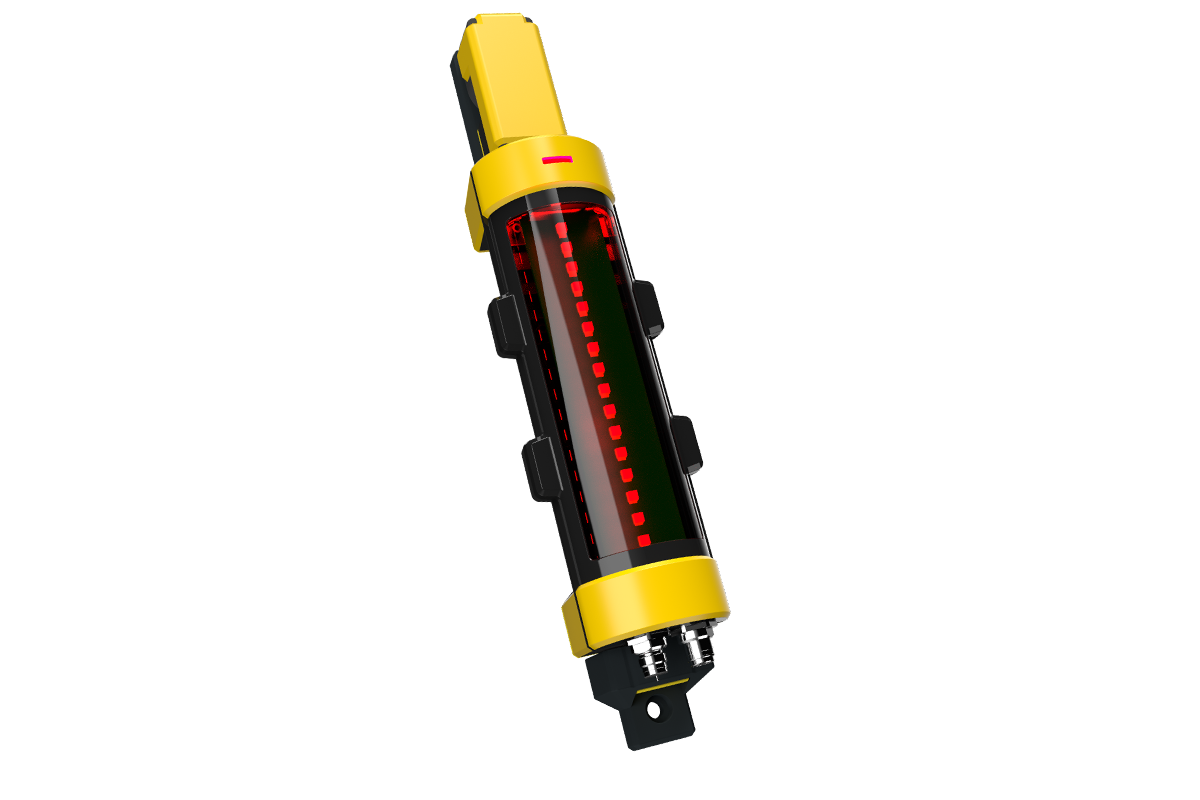

Laser Receiver

*optional

G3 Sensor

bucket, arm, boom, frame (+ tilt optional)

GLOBAL DISTRIBUTION & LOCAL SERVICE

In addition to our US headquarters, MOBA is represented by its subsidiaries in Europe, South America, India, Asia and Australia, and by a worldwide dealer network in all key markets in the sectors it serves.