See MOBA’s Technology Lineup at CONEXPO-CON/AGG – Central Hall Booth C32342

March 3–7 | Las Vegas Convention Center

CONEXPO-CON/AGG is where the construction industry comes to see what’s next—and MOBA will be in Las Vegas showcasing proven technologies that help contractors, OEMs, and fleets work more accurately, efficiently, and profitably.

From paving automation and machine control to on-board weighing and smart signaling, MOBA solutions are built for real-world performance—and designed to scale with your business.

What You’ll Experience at the MOBA Booth

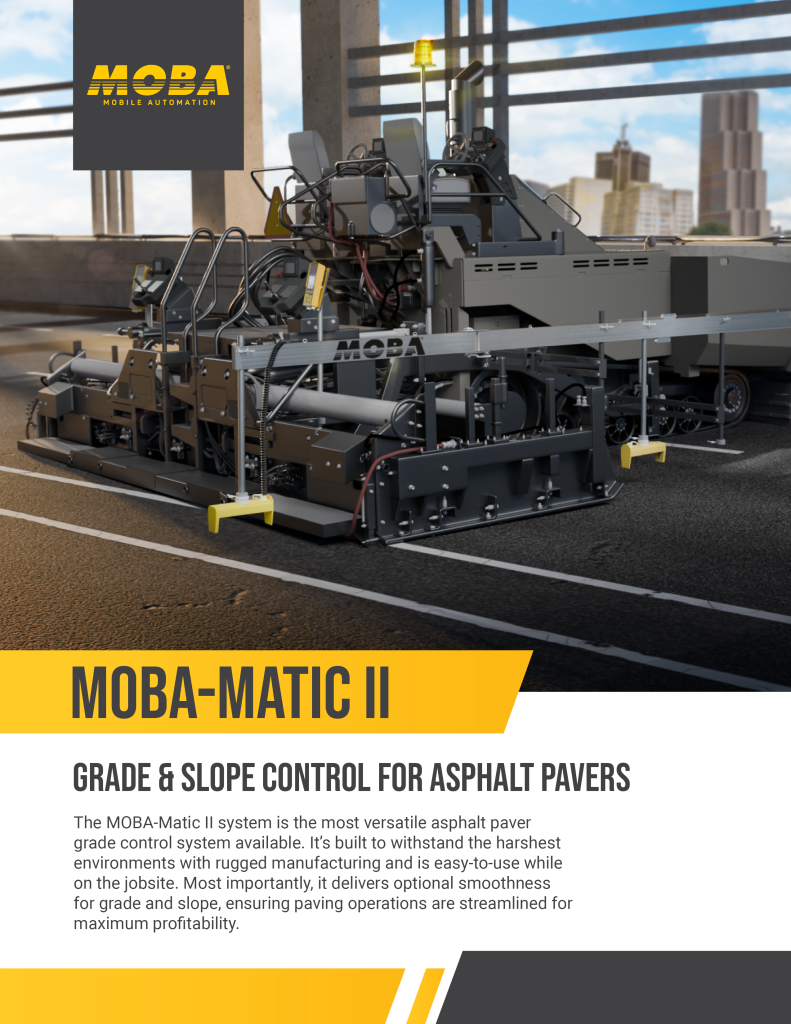

Paving Solutions Focused on Quality

MOBA’s paving technologies support smoothness, material consistency, and temperature insight—helping crews reduce rework, improve mat quality, and increase operational confidence.

HLC-4000: On-Board Weighing for Wheel Loaders

The MOBA HLC-4000 delivers accurate, operator-friendly payload weighing that improves loading precision, reduces overages, and strengthens jobsite efficiency. It’s a smart step toward better material accountability and margin protection.

Xsite® Easy: Practical 2D Excavator Guidance

Xsite Easy provides intuitive 2D machine guidance for excavators—reducing over-digging, improving grade accuracy, and helping contractors increase productivity without unnecessary complexity.

Laser Guidance & CAN-Based Display Platforms

See the R.45.TC and R. 45. PRO laser receivers for excavators, along with CB.D3.CAN and DUO3.CAN display platforms supporting modern CAN integration and customizable signaling solutions for OEM applications.

MOBA Innovation Center Approach

Learn how our Innovation Center model brings engineering, validation, and collaboration together to accelerate product development and support OEM growth programs.

Why Visit Booth C32342?

- Live product demonstrations

- Hands-on configuration tools

- Direct conversations with MOBA experts

- Insight into improving predictability, scalability, and margins

If you’re attending CONEXPO-CON/AGG March 3–7, make time to visit MOBA in the Central Hall, Booth C32342.

Let’s talk about how smarter systems create stronger results.